A mark that has

remained since 1974

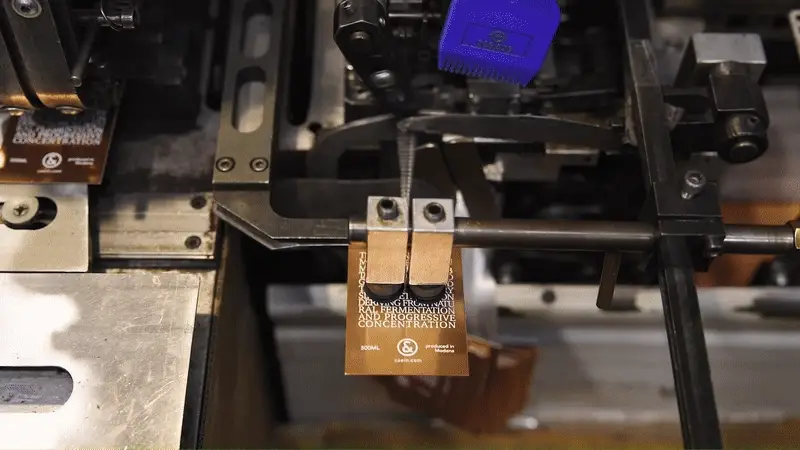

A modern typography, industrial in its efficiency, artisanal in its care

Since 1974, we have been transforming paper, fabric, and materials into tangible signs of identity.

We were founded in Granarolo dell’Emilia, surrounded by factories, workshops, and printing houses: an area that moves to the rhythm of a job well done.

In over fifty years, we have learned that a tag is never just a piece of paper: it is the first gesture that introduces a brand, a touch that remains between your fingers, a small object that carries with it memory and recognizability.

For us, “TAG” is not just a tag, but a verb: it gives a name, an identity, and value to what you produce. From the tag, all the other packaging solutions were born, with which we express the soul of our customers every day, transforming a detail into a bridge between brands and people.

Our evolution

Our history is one of continuous progress: from the first printing presses to digital systems, NFC technologies, and special sustainable projects. Each innovation has been adopted to combine speed, quality, and new creative possibilities.

1974

CO&IN is founded, starting with the resale of clothing accessories. Our first logo, an avant-garde retro look for its time.

1983

The obligation to have a composition label on garments comes into force, the first rotary label printing machines.

1986

1990

Introduction of Computer to Plate with the first Macintosh, Adobe Illustrator 88, Adobe Photoshop 1.0, Adobe Font Folio, Postscript 1.0, Purup ImageMaker 80/10 imagesetter.

1994

2000

2013

First 5-colour white + four-colour digital printer for variable data Ricoh 7100X.

2017

2018

System certification journey supporting corporate sustainability and debut at Packaging Première Milan.

2020

2022

2022 installation of first KBA Rapida76 5 colors + bivalent flexo spreader for traditional and UV printing.

2025

Repowering the 190 kWh photovoltaic system and fully heat pump heating, resulting in zero methane gas consumption and the greenhouse effect.

2026

The Smart Tags are here: innovation, security, and branding in a single tool.

1974

CO&IN is founded, starting with the resale of clothing accessories. Our first logo, an avant-garde retro look for its time.

1983

The obligation to have a composition label on garments comes into force, the first rotary label printing machines.

1986

1990

Introduction of Computer to Plate with the first Macintosh, Adobe Illustrator 88, Adobe Photoshop 1.0, Adobe Font Folio, Postscript 1.0, Purup ImageMaker 80/10 imagesetter.

1994

First 4 color offset 35×50 Komori L420, we start working with the foreign market, France in particular.

2000

Third Komori L228 with in-line UV coater, first Exacta machine for automatically threading eyelets/cords/pins into tags. Expansion and new image.

2013

First 5-colour white + four-colour digital printer for variable data Ricoh 7100X.

2017

Installation of photovoltaic panels equal to 100 KWh of power.

2018

System certification journey supporting corporate sustainability and debut at Packaging Première Milan.

2020

Start of energy and aesthetic redevelopment of offices and production.

2022

2022 installation of first KBA Rapida76 5 colors + bivalent flexo spreader for traditional and UV printing.

2025

Repowering the 190 kWh photovoltaic system and fully heat pump heating, resulting in zero methane gas consumption and the greenhouse effect.

2026

The Smart Tags are here: innovation, security, and branding in a single tool.

People, not roles

Every day, our team shares the same table: designers who draw lines as thin as threads, printers who listen to the sound of paper and printing presses, consultants who transform questions into solutions.

At CO&IN, work is not a chore, but something we truly enjoy. A peaceful and creative environment where ideas intermingle and take shape. Those who enter our workshop find a partner, not a supplier: a group of passionate professionals who accompany you step by step, with humility and practicality, to transform ideas into materials you can touch, see, and feel.

Quality, precision, and creativity in every detail

For us, quality is not a goal, but a method. From design to printing, every stage is checked to ensure aesthetic consistency, technical soundness, and fidelity to the customer’s vision. Every project begins with listening. The first step is always to understand what you want to say and how you want to be perceived. From there, we build a path that is both technical and sensory to create projects that are never standardized but always tailor-made, with artisan expertise applied to industry.

Dialogue

We sit down with you, gather insights, objectives, and reference materials.

Translation

We transform ideas into prototypes, print proofs, and samples you can browse and touch.

In-house production

Our machines, our team: everything under control, guaranteed delivery times, no change of hands.

Delivery and continuity

Small batches or complex productions, always with the same attention and care.

Printing techniques

Each printing technique is an alphabet with which to write your story: the soft relief of letterpress, the glow of holographic foil, the depth of a bas-relief, the matte caress of soft-touch lamination.

Direct printing

Letterpress

Digital printing

Matte solvent ink

Thick glossy UV ink

Special ink

Hot foil

Cold foil

Holographic foil

Recyclable hot foil

Foil finishes

Embossed and tactile finishes

Bas-relief

Shiny raised Braille

Soft-touch lamination

Embroidery

Applications

Laser

Customized techniques

The materials

Every material has its own voice: natural papers that rustle, textile fibers that warm to the touch, materials that tell stories.

Cards

Natural cards

uncoated, with a more textured surface.

Recycled paper

made from recycled, sustainable fibers.

Pulp-dyed paper

color integrated into the fiber, high lightfastness.

Coated paper

smooth surface, suitable for sharp prints and photo-quality images.

Marked, embossed, and laid paper

with surface textures for tactile and visual effects.

Parchment paper

with a semi-transparent and satin finish.

Thick paper

Resistant, ideal for high-quality packaging.

Custom cards

customized paper in terms of weight, color, and finish.

GRS cotton (certified recycled)

sustainable, natural, and certified material.

Resin-coated anti-fraying cotton

treated for greater strength and durability.

Natural yarn

natural fibers such as cotton and linen, for an elegant and authentic look.

Recycled yarn

made from recycled materials with low environmental impact.

Polyester satin

Shiny, soft fabric, ideal for ribbons and refined finishes.

Double polyester crepe

Thicker, with a glossy effect on both sides.

Grossgrain

ribbed fabric, very durable, with an elegant look.

Organza

Lightweight, transparent fabric with a sophisticated effect.

Recycled linen

natural fiber with a distinctive texture, in a sustainable version.

Felt

Soft and thick, excellent for labels or textured details.

Textile materials

Technical and special materials

Tyvek

synthetic material, tear-resistant and water-resistant, similar to paper but more durable.

Polypropylene

Versatile and lightweight plastic material.

Recycled PET

Recycled plastic material, sustainable and resistant.

Sustainability is not a trend, but an everyday gesture

We use recycled paper, natural fibers, and certified yarns; we reduce waste and choose low-impact processes.

But for us, sustainability also means ethics: respect for those who work with us, care for the local area, and responsible, lasting relationships.

Recognized value, in black and white.

Our choices are certified by international bodies:

FSC®

Since 2018, we have guaranteed paper sourced from responsibly managed forests.

OEKO-TEX®

STANDARD 100 by OEKO-TEX® guarantees safety and the absence of harmful substances in fabrics.

GRS

The Global Recycle Standard, promoted by Textile Exchange, certifies the quality and traceability of recycled materials.